The push for sustainability is driving innovation. How can the digital print industry play its part in cleaning up textile’s dirty image?

Fashion has an image problem. According to a 2021 report by UBS Investment Bank, the apparel and textiles industry emits more CO2 than aviation and shipping combined, Twenty percent of the world’s industrial water pollution, and consumes 79 billion cubic metres of water annually.

There is no quick fix. Textiles is a complex, global business, with myriad processes and sub sectors along the value chain. And though it is only a small link in that very large chain, digital print has a role to play as part of the solution. “Traditional textile printing requires washing and steaming to fix dyes, which consumes large amounts of water and energy,” says Andy Gregory, sales director of UK Mimaki distributer, Hybrid Services. “Water is also required in the screen manufacturing process, as well as post printing, to wash off screens and equipment. Steaming and washing is also needed even when digital printing with reactive and acid inks, to ix the inks to the fabric.”

Industry-wide, efforts are being made to reduce waste, decrease energy consumption, and shift to less harmful materials. Digital printing is already more sustainable than traditional processes, and innovations in eco-friendly inks, UV, and latex printing are just a few solutions manufacturers are exploring.

“It’s important to take a holistic view of the system when calculating overall running costs.” – Andy Gregory, sales director, Hybrid Services

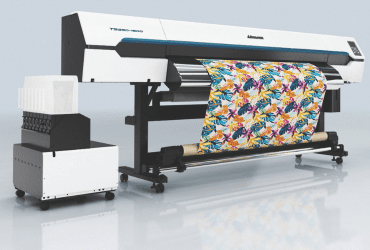

Mimaki’s Trapis system, for example, combines a printer and a transfer system using less energy, fewer processes, and virtually no water. Crucially, it maintains quality while simplifying textile printing.

“Trapis combines high quality pigment inks with a straightforward heat transfer process and eliminates the need for complex pre- and post treatment steps,” explains Mr Gregory. “It also significantly reduces water and chemical usage compared to some traditional and digital textile printing methods.”

Mimaki’s Trapis system can be used for a variety of applications. Can its eco-credentials set a precedent for the industry?

Mimaki claims Trapis has a carbon footprint 92% lower than conventional dyeing methods. Furthermore, the system – ideal for applications from soft furnishings to clothing, and even large-scale signage – throws down a gauntlet for the rest of the industry. It raises the bar for sustainability but lowers the barrier to entry.

“Unlike traditional textile printing onto natural fabrics, which requires specialist knowledge as well as fabric preparation and complex finishing, Trapis is a compact, easy-to-use system requiring no pre-treatment, and is simple to finish. This makes high-quality textile printing accessible to designers, start-ups, education establishments and businesses of all sizes,” says Mr Gregory.

With any new technology there is always the question of costs. If digital printing cannot compete in this area, uptake will be slow. However, while any investment in equipment is substantial, Mimaki believes the ongoing savings are worth it.

“With no pre-treatment for the fabric required, cost and time savings can be made on the base cloth, printing to paper is easier, faster, and more reliable than direct to textile – so both time and money can be saved there,” explains Mr Gregory. “There are further savings to be had in the finishing process too, so it’s important to take a holistic view of the system when calculating overall running costs.”

Clearly, the need for sustainability is driving change in the industry. By lowering barriers and raising standards, innovations like these are helping to make sustainable textile production a reality – not just for big manufacturers, but for everyone.