Jamprint Design & Printing has installed a Mimaki UJV55-320 UV LED roll-to-roll printer from CMYUK, marking its first in-house super-wide printer and expanding opportunities in textile, SEG and single-piece wallcovering applications.

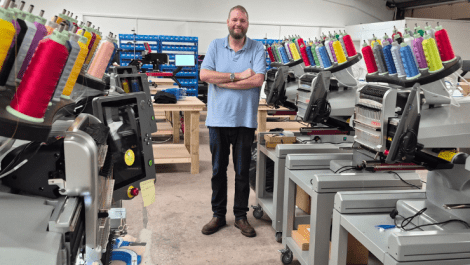

The new 3.2m-wide printer enhances Jamprint’s large-format production hub in Calne, Wiltshire, led by sales and operations director Adam Moss. It complements the company’s Swindon site, which houses litho, small-format digital, and finishing operations.

Founded in 2008 by Jason Miles, Jamprint has grown as a family-run business, with nephew Jake Fortune now serving as managing director and his brother Kieran heading up the Stroud-based specialist arm, Majuba. “Diversifying beyond litho and digital has been a strategic goal for us, and client demand for 3.2-metre-wide banners and textile applications made the decision straightforward,” said Mr Fortune. “The Mimaki UJV55-320 gives us the width, quality, and reliability to bring work in-house, increasing turnover in a different part of the business, and gives our customers faster lead times.”

The Mimaki printer will produce banners, tension frame graphics, single-piece wall coverings, canvases, and construction or scaffold banners – all sectors where Jamprint is seeing growth. “We looked at alternatives but the Mimaki’s balance of image quality and total cost of ownership stood out. It’s a genuine workhorse, simple to operate, and fantastic value,” added Mr Fortune.

To complement its expanded soft signage capability, Jamprint has also introduced in-house industrial sewing for hems and keder, allowing complete SEG and banner finishing under one roof. “Initially we expect to save at least £3,000 per month that would otherwise go to outsourcing, and that’s before you count the gains in speed control and client satisfaction,” Mr Fortune added.