Fiery has announced the release of v11 of Digital Factory Rip and workflow software with enhanced features for direct-to-film (DtF), direct-to-garment (DtG), UV/LED, dye sublimation, toner transfer and wide-format print/cut applications, providing colour management, white ink handling and automation and e-commerce integration tools.

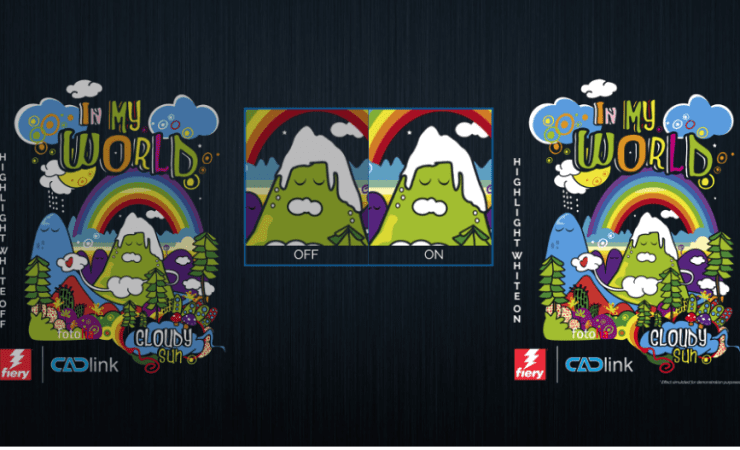

The software, formerly CadLink until its acquisition by EFI (now Fiery) in mid-2022, features a patent-pending white ink management technology that is claimed to be unique. This enables single-pass printing of ‘whitest’ highlight white or underbase, resulting in more vibrant colours and reducing print time. It also includes a variety of job preparation and automation tools that are said to maximise productivity and throughput while minimising production errors.

‘We are very excited about the release of Digital Factory v11. The features included in it were specifically developed based on feedback from our key stakeholders – manufacturers, dealers and most importantly, our customers,’ said John Henze, vice president of sales and marketing at Fiery. ‘For example, the single-pass highlight white/underbase feature is truly revolutionary when printing with white inks, making white highlights within the design ‘pop’ off the garment by being significantly brighter. In addition to this, the new automation as well as e-commerce related features enable users to achieve their business objectives by providing the tools needed for high quality, high volume production all using a single software platform.’

‘The incredible growth that the Digital Factory software solutions have shown over the past three years across all speciality print platforms, particularly in the direct-to-film market, demonstrates how essential they are to end-users and equipment suppliers like ourselves,’ commented Don Copeland, digital products manager at Coldesi, a supplier of turn-key digital print and apparel decoration solutions.