With two major international shows that include digital textile printing equipment, consumables and software running only two weeks apart, we’re arguably spoiled for choice in terms of real-world events to go to. Here’s some of what will be on offer at each.

Fespa, 23–26 May, Messe München, Germany

The annual European event for the wide-format signage and display sector has increasingly been featuring textile print applications in recent years. Here are some highlights.

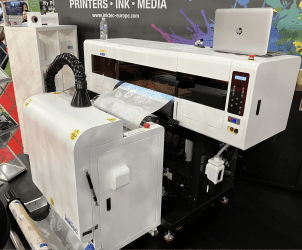

Azonprinter has announced what it describes as ‘the only 24-in DtF system that is completely maintenance-free’. The 60cm width printer range encompasses ‘Primo+ Neon’ and ‘Primo+ Neon X’ (CMYK, white and four neon colours) colour options.

The machines feature built-in ink tank agitation and recirculation systems, and an automatic nozzle check with a programmable schedule. The system features automatic maintenance and uses bulk ink in 750ml tanks. The printer is equipped with the Industry Signal Light for visible status of the DtF system and there is an LCD colour touch screen for control. The machines are driven by the Fiery Rip for fast and precise colour prints, with ICC profile and Pantone colour support.

Berger Textiles will launch a new architecture product range for interior architectural applications. The new offering includes Shift, a printable odour control textile, specifically engineered to absorb and neutralise odours such as kitchen or animal smells and cigarette smoke in a variety of environments, as well as capturing and neutralising formaldehyde. It can be used in display frame systems, banners and interior panels, and is printable via direct or dye sublimation printing.

The second new material is Absorber, which offers two different noise-absorbing materials, designed to improve acoustics in a range of settings, from corporate offices to leisure and hospitality spaces. They can be used in aluminium frames or plastic profiles or for frames and built-in structures. Both materials are suitable for a wide range of architectural applications.

Heytex offers textile blockouts in various designs, which it manufactures in Germany. These are textiles that do not allow light to pass through and are therefore well-suited to applications such as roll-up displays, exhibition stands or room dividers. All Heytex textile blockouts are PVC-free, available in widths up to 505cm, seamless and flame retardant to B1 standard. At Fespa, the company will introduce new sustainable variants to its portfolio.

Nightfever Blackback comes in soft and recycled carrier fabric variants for indoor use, while PVC-free Ecotex Blockout Whiteback can be supplied CO2-neutral on request and is printable on both sides for outdoor use. Another addition is Doubleface Whiteback, an indoor banner alternative which is curl-free and identically printable on both sides; Whitenight Soft Whiteback is a soft blockout, printable on both sides for indoor use. Skylight B1 is designed for backlit UV or latex-printed applications, with a textile surface.

InkTec manufactures inkjet inks, printers, and printing solutions for a range of industries, including textiles, signage, and graphics. At Fespa, it will be showcasing several new products that offer a fresh perspective on printing technology. These will include the first international showing of its complete range of DtF products. This range includes a 60cm printer, compact shaker, air purifier, high-quality inks, PET films and hot-melt powder, as previously reported by Digital Textile Printer in our review of Printwear & Promotion earlier this year. InkTec staff will be on hand to demonstrate the ease of use and versatility of the DTF range and to answer any questions. Another highlights of the InkTec stand will be a new 3.2m UV LED Roll-to-Roll Printer, the Jetrix XGR320.

InkTec’s DtF machine boasts a very compact footprint for the shaker section

Mimaki will highlight the new TxF150-75, its first venture into the DtF sector, but far from the company’s first foray into textile printing, where it has been active since the late 1990s. Suitable for producing a print onto cotton, polyester and polyester blended materials, the TxF150-75 includes a white ink to enable the print to be applied to both light and dark coloured fabrics. The new model removes the labour-intensive process of plate creation in screen printing and the required weeding in traditional vinyl heat transfer.

‘The new Mimaki TxF150-75 is designed to fit with businesses of all sizes. Small companies that have a need to run the machine a few hours a week are catered for as capably as larger organisations that have high volumes of output, with both benefiting from a reliable solution that maximises productivity and reduces waste,’ stated UK distributor Hybrid’s Duncan Jefferies.

Ricoh says its exhibit at Fespa will focus largely on textile printing, featuring new, enhanced and collaborative technology including both DtG and DtF machines. Several product developments will be shown in Europe for the first time in Munich. These will include a polyester direct-to-garment printer and a new digital textile printer, designed to achieve ‘highly vibrant colours for impactful designs’ in DtG and direct-to-film printing. The company will show a new roll-to-roll DtF production system as well.

These capabilities will be further demonstrated by Ricoh’s partnership with Fruit of the Loom and Russell Athletic. Ricoh will present a showcase where visitors can custom design their own T-shirt and see it produced on the stand. Demonstrating how creative designs are brought to life will be Manga artist Shinnosuke Uchida; during the event visitors will be able to watch the artist work live as she shares her own take on the spirit of Japan.

ColorGate (part of Ricoh since its acquisition in late 2018) will demonstrate how its Productionserver Rip and workflow software can achieve high quality colour-accurate production across the various print devices, ink types and adhesion technologies.

SAi, developer of the Flexi signage and print-and-cut design and Rip software, will show Flexi 22, the most recent revision of its flagship product for the sector, which includes specialist tools for direct-to-film and direct-to-garment design and production. The company says these features can help signmakers expand into new markets and offer additional services to their existing customers.

Flexi 22 includes the SAi Connect dashboard for monitoring production data, licenses, subscriptions and downloading updates. The ability to modify jobs directly within Flexi Production Manager helps streamline workflow, while repeat jobs are easily accessible with their original settings for faster, easier and more profitable reprints.

ITMA, 8–14 June, Fiera Milano, Italy

ITMA is the major gathering place for the textile and garment production industry, a four-yearly opportunity to take stock of the latest developments, technologies and trends. Digital print will be a small but significant and rapidly-growing part of that.

EFI Reggiani will be focusing on its Eco Terra fabric printing system, which it describes as an all-in-one solution for pigment printing that requires no ancillary equipment for pre- and post-treatment. By combining inline printing and finishing, EcoTerra is said to offer minimal water consumption both within the printer and for the overall process, in addition to reduced energy consumption and carbon footprint. The pigment-based EcoTerra ink range features seven colours – cyan, magenta, yellow, black, blue, red and green – for an expanded colour gamut, while an enhanced polymerisation and finishing unit also gives the fabric a softer hand feel, with excellent wet and dry fastness and a high level of sharpness and detail in the printed image, while also meeting global regulations and industry standards.

‘Improving sustainability in the textile industry is one of the key drivers for our development roadmap,’ says Micol Gamba, senior manager, product marketing. ‘EFI Reggiani EcoTerra in particular has been conceived to respond to the demand for a more sustainable printing process, reducing chemicals, energy and water consumption, and at the same time ensuring a fast time-to-market to provide a solution for on-demand manufacturing.’

Kornit Digital will unveil its Apollo direct-to-garment platform alongside an expanded end-to-end fulfilment ecosystem at ITMA. Built on the company’s Max technology, Kornit Apollo delivers retail quality with full automation control and integrated smart curing processes. The company says it’s the most comprehensive digital solution for both nearshore short- and medium-run mass production, delivering optimal total cost of ownership and 400 prints per hour, per operator.

In addition to Apollo, Kornit will present three systems for sustainable, on-demand fulfilment. Atlas Max offers industrial-scale mass customisation, enabling greater efficiencies and reducing operating costs, combined with XDi technology to emulate screens, vinyl, 3D and threadless embroidery effects in one automated production system, while Atlas Max Poly extends these capabilities to polyester and poly-blends, addressing the recreational and professional sports apparel markets.

Kornit Presto Max is claimed to be the most capable, sustainable, single-step digital solution for direct-to-fabric decoration, and the only digital solution for white printing on coloured fabrics for fashion, home décor and other applications.

Mimaki is exhibiting at ITMA as well as at Fespa. In Milan, as well as showing the TxF150-75 DtF printer (see Fespa section above), it will also feature the TS330-1600 high-volume dye sublimation printer. This 1600mm-width printer has a maximum print speed of 135sqm/hr, supported by a 10kg ink supply and improved take-up mechanism; it is also able to print with fluorescent colours for a wider range applications.

Several new models, including a brand-new textile printer, will also be debuted at ITMA, according to UK distributor Hybrid Services. The Mimaki stand will also feature examples of collaborative projects with a global roster of design talent, from the US, Australia and Italy.

Paper and other woodfibre products manufacturer Sappi will be present at ITMA with its stand theme ‘fashion meets forest’. In terms of products, this means its Transjet and Basejet ranges of dye sublimation transfer papers, and its Verve dissolving pulp offering, which feeds into the manufacture of rayon fibres for Lyocell and viscose.

From the former category, various sublimation papers with optimised qualitative properties will be on show. These are said to feature excellent ink release and density, a high transfer rate, low ink consumption as well as enhanced protection to reduce textile shrinkage. To support these, Sappi has opened a new warehouse at its Carmignano mill in Italy. Coming months will see further investment in two new converting machines with widths of 1.9 and 3.2m, plus a fully automated packaging line.

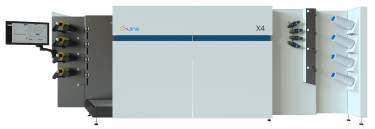

The Twine X4 offers on-demand digital dyeing of threads and yarns

Twine produces digital thread and yarn dyeing systems and will present its next generation of waterless digital dyeing system for textile manufacturers. The Twine X4 supports an average dyeing speed of 21.6km/hour, suiting cut and sew production, decorative knitting and ribbon weaving applications. The system offers on-demand in-house digital dyeing for threads and yarns, optimising production processes and achieving unmatched levels of accuracy, speed, efficiency and sustainability, according to the company. Its upgraded capacity can dye up to two tons of thread/yarn annually.