American Print & Supply (APAS) has launched The Sentinel, a vision-driven laser cutting system designed specifically for Direct-to-Film (DTF) transfers. The system was introduced publicly at this year’s Printing United Expo in Orlando.

According to the company, The Sentinel is intended to automate one of the more time-consuming stages of DTF production by removing the need for manual trimming and eliminating reliance on DXF or CAD-based cut files. APAS founder and CEO Rob Super said the cutting stage has become an increasing bottleneck as printer output speeds rise.

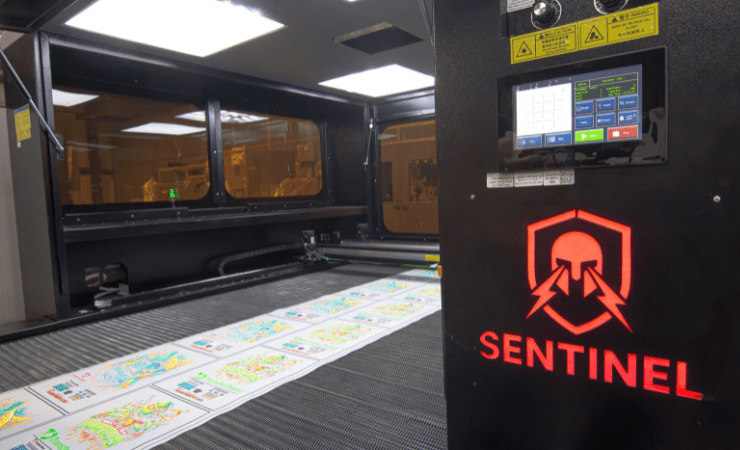

The Sentinel uses an overhead HD camera to scan printed rolls in real time, automatically identifying cut paths without additional file preparation. For users of APAS’s Gangify gang-sheet software, visual cut marks are generated automatically, allowing sheets to be printed and fed directly into the cutter.

The system features dual servo-driven C02 laser bridges, a 64-inch bed, and the capacity to run two 32-inch rolls simultaneously. APAS reports that the servo rack drive system provides greater accuracy and durability than belt-driven mechanisms, with internal testing achieving cycle times below three seconds per transfer and throughput exceeding 750 cuts per hour. An integrated exit conveyor enables continuous operation.

Safety features include a fully enclosed cutting area, tinted viewing panels, ventilation, and interlock shutoffs. Additional functions comprise a dual-roll feeder, continuous-feed conveyor, and a perf-cut mode for producing pre-separated rolls.

APAS says The Sentinel is compatible with its full range of printers, including the Kraken, Hydra, and UFO models, and can also be used alongside equipment from other DTF manufacturers. The company positions the system as suitable for shops looking to streamline cutting workflows or expand into higher-volume production.