Durst Group’s P5 500 TEX iSUB printer is seeing strong early adoption and performance in real-world production environments, as soft signage producers seek to streamline operations and reduce environmental impact.

First shown at Fespa in Berlin earlier this year, the 5.2-meter-wide dye sublimation printer stands out for its integrated inline fixation – a feature that eliminates the need for a separate heat calendar, said Durst. By combining printing and fixation in one workflow, it reduces equipment footprint, energy usage, and production time.

German print specialist Procedes became the first company to install the P5 500 TEX iSUB as part of a field-testing partnership with Durst. Since July, the system has been running under full production conditions, with feedback helping to refine performance and validate efficiency claims.

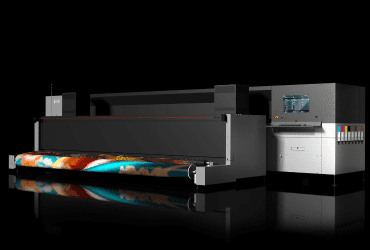

Durst’s P5 500 TEX iSUB

“This collaboration allows us to gather valuable insights while ensuring the system meets the highest quality and reliability standards,” said Christian Harder, chief sales officer at Durst Group.

The printer enables seamless 5-meter-wide textile outputs without stitching, reducing manual handling and improving visual quality. In addition, the printed materials can be folded, which cuts down on transport volume and shipping costs – key benefits for service providers looking to boost flexibility and reduce delivery times.

Market response has been positive, with the company reporting strong sales in the first two months after introduction. The P5 500 TEX iSUB is positioned as a solution for print businesses seeking greater sustainability and throughput in large-format fabric printing.

As the demand for soft signage continues to grow across sectors such as retail, events, and exhibitions, Durst’s system appears to be addressing a clear need for efficiency, quality, and reduced environmental impact.