Stahls’ has announced a series of updates to its product and technology offerings, aimed at improving production efficiency, expanding creative capabilities, and supporting environmentally responsible practices in garment decoration. They will be presented at Fespa in Berlin, Germany.

The company’s UltraColor Max Direct-to-Film (DTF) transfers now incorporate proprietary ink technology that increases the colour gamut by 23%. The update results in finer detail and improved vibrancy. The new formulation is also free from ethylene glycol and formaldehyde, and meets safety and environmental certifications, including OEKO-TEX, Prop 65, and CPSIA.

Stahls’ is also rolling out its Fulfill Engine software in Europe. Originally launched in North America, the platform provides an integrated solution for print-on-demand operations, covering product creation, order processing, and fulfilment. The tool is designed to help streamline workflow and scale operations more efficiently.

In materials development, the company will present its new TPU emblem technology manufactured at its Madrid facility. These emblems are designed to offer a durable and dimensional finish for garments, providing an option for applications requiring a more structured or premium look.

Stahls’ will also showcase its expanded heat transfer vinyl (HTV) range, adding new textures and finishes to give decorators additional flexibility in design.

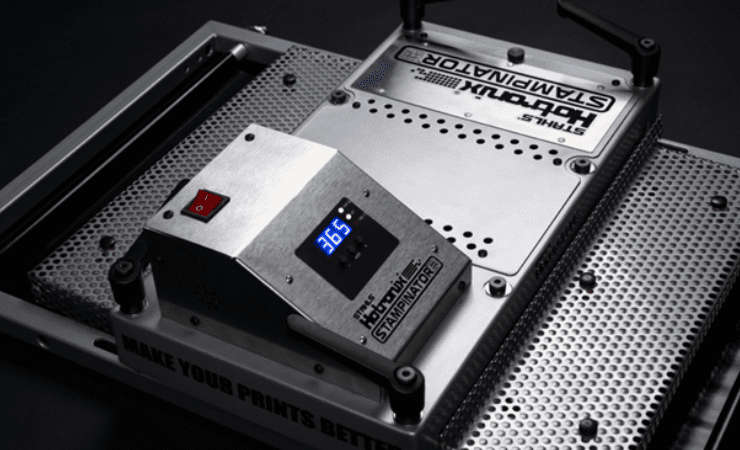

A notable development on the production side is the integration of the Stampinator with Hotronix equipment. The system allows screen printing presses to function as high-throughput heat presses, supporting tasks such as pre-pressing, curing, and applying DTF transfers. It includes digital temperature controls and is capable of processing more than 480 units per hour. This solution is intended to increase consistency and reduce bottlenecks in high-volume environments.