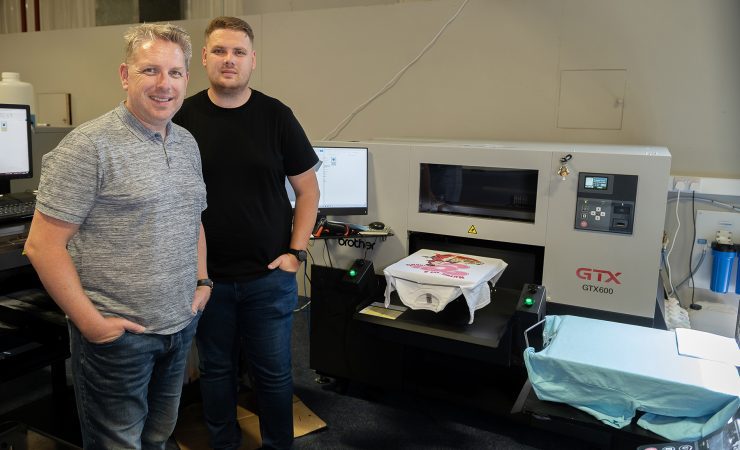

Swindon-based PrintClever reports it is on track for an £8 million turnover this year after launching a direct-to-garment factory with a £500,000 spend that included eight Brother DTG printers.

The business, which was founded by CEO Ryan Acres eight years ago in his parents’ garage, now employs 80 people and works for various major brands, music corporations, gaming companies and a Hollywood film production company.

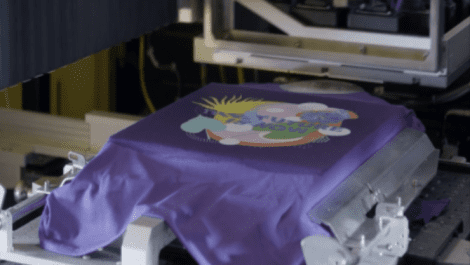

The expansion of premises and equipment began in March 2022, and included eight DtG printers from Brother – four GTX Pro Bulks and four Brother GTX600s. These were complemented by four Schulze pre-treatment machines, three Chiossi e Cavazzuti tunnel dryers, a Chiossi e Cavazzuti T-shirt folding line and two Melco embroidery machines.

The factory can now produce 3000 printed garments a day and with the Christmas rush has taken on additional seasonal staff and is running 24 hours a day, producing a finished garment every 35 seconds.

Mr Acres said, ‘Back in March 2022, we took a bold step forward into the direct-to-garment industry, buying our first Brother machine.

‘Fast forward 20 months and we’ve really made our entrance into the market, becoming one of the UK’s largest print-on-demand garment manufacturers. It’s been an incredible journey.’

He also told Digital Textile Printer, ‘We spent some time looking at DtG printers with numerous major manufacturers but the Brother machines really stood out for us. We wanted to invest in fast, well-priced and easy-to-manage printers – and the GTX Pro Bulks and GTX600s are just that.

‘In the past we’ve had to call out engineers to maintain some of our printers, but our new Brother machines are easy to look after in-house; a number of our DTG staff have been trained on carrying out maintenance, which helps reduce the overall running costs and downtime.’