An Aeoon industrial DTG printer supplied by Xpres is a key part of production at the UK’s TOT Shirts, where it is producing up to 1600 prints every day.

Based in North London, TOT Shirts is one of the UK’s leading T-shirt printing and garment decorators. Founded in 1985 it has built a reputation for quality and has a diverse customer base which includes music merchandisers, fashion designers, retail brands, sports clubs, corporate clients and the promotions sector.

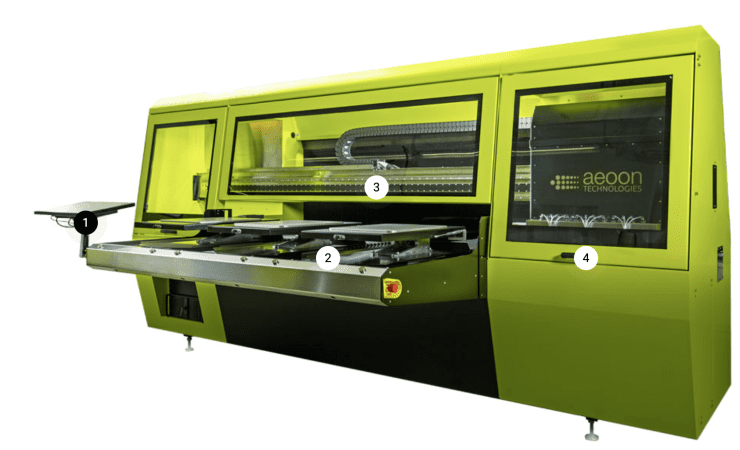

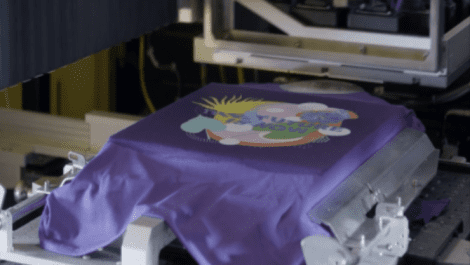

Whilst a significant proportion of the millions of garments decorated annually by the company at its 75,000sqft facility are screen printed or embroidered, this was complemented some years ago by investment in direct-to-garment technology and the acquisition of an industrial speed Aeoon Kyo DtG printer equipped with three platen print stations.

Within the DtG department, the Kyo quickly became valuable, enabling TOT to supply more detailed, short-run prints with a faster turnaround and without the origination or set-up costs attached to screen printing. The team keeps the Kyo in good working order and are highly proficient with machine’s maintenance and cleaning schedules, enabling it to consistently producing up to 1600 high quality prints each day.

Since installation, the machine has been subjected to numerous updates; TOT Shirts subscribes to the theory that, like many finely-tuned pieces of engineering, they run at their best when used correctly and frequently. This proactive approach to upgrades and scheduled maintenance, supported by Xpres, enables the business to consistently deliver high-quality prints. Jason Frost of TOT Shirts commented, ‘Xpres have an excellent team of engineers and their comms have been first class. So a huge thanks to the team for the efficiency and triage of any issues while delivering these upgrades.’