Resolute DTF has launched a new multi-function DtF and other large format print device at The Print Show in Birmingham, plus a novel powderless DtF system.

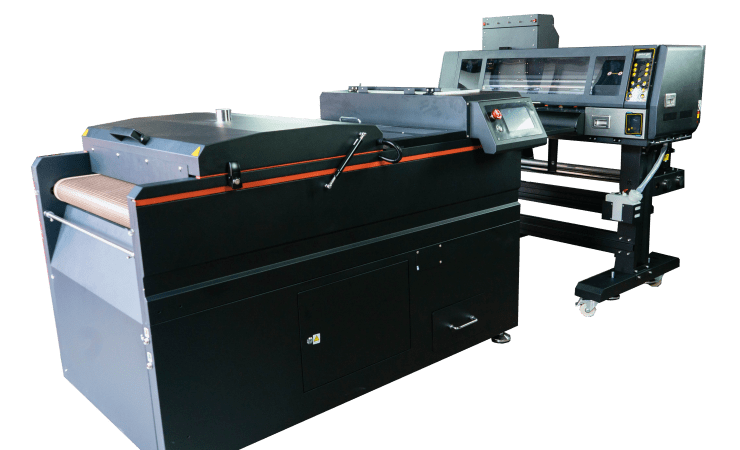

The latest iteration of Resolute’s R-Jet Pro line is the Multi-Function V series of 60cm width printers. The R-Jet Pro DTF V4i handles DtF thermal transfer media plus automated powder application and curing but can also print onto aqueous vinyls, self-adhesive and other large format media to produce items such as posters and labels, potentially combining two different print types into one unit, bringing greater flexibility and reduced cost and footprint. It uses DuPont Artistri inks which have Oeko-Tex, GOTS and HAPS (non-hazardous air pollutants) certifications.

A powderless DtF system was also revealed. The R-Jet Pro DTF NP3 is a third-generation device that uses a water-based and Oeko-Tex approved clear adhesive that is jetted onto the transfer media via a dedicated printhead after the CMYK and white inks. This yields a very soft feel and good stretchability in the transferred material on the finished garment, as well as saving the space and cost associated with a power shaker and curing unit, though there is an air dryer to treat the printed film as it emerges from the printer. The dried film is stable and can be rolled and stored for subsequent transfer.

Resolute director Colin Marsh told Digital Textile Printer that the new generation provides better results on cottons than the previous ones, as well as on polyester and other fabrics. He also noted that it is possible to print adhesive only, allowing for creative applications using hot foil transfer. The printer can be used as a ‘regular’ DtF machine by not printing the adhesive, for applications that might require greater adhesion and wash durability such as healthcare uniforms, though Mr Marsh said that the powderless version had been subjected to a 28-wash cycle with satisfactory results.

The Pro DTF NP3 is driven by a dedicated built-in Fiery Rip that can also handle cutting instructions and data for downstream finishing processes.

The other addition to the R-Jet Pro V range is the V8, a higher performance system capable fo 28 linear metres per hour output (mono) or 20lm/hr in colour. It can be coupled with a semi-automatic flatbed cutter, it can enable one operator to print and cut 100lm of DtF transfer per day. It is driven by Resolute’s Fiery-based Rip V11, which can impose files to maximise media usage and to generate cut files, or to pass through those generated with the artwork.