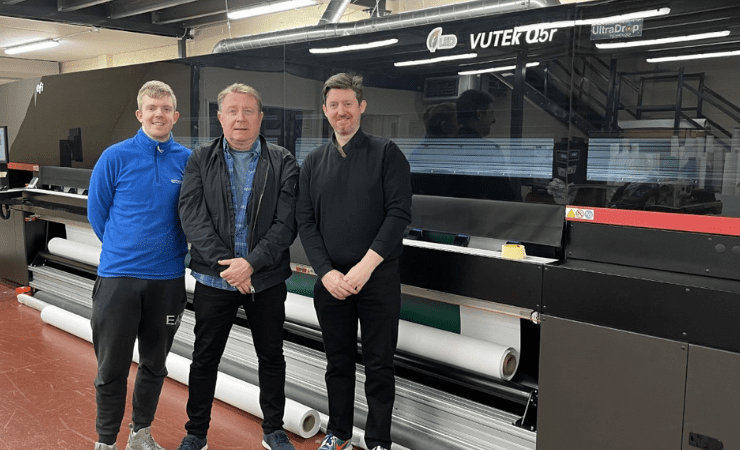

CoverUp has installed an EFI Vutek Q5r printer as it looks to achieve faster print speeds and higher quality output. The printer, which incorporates an automatic inline finishing system for printing, cutting, slitting and collection all on the same platform, was purchased through CMYUK.

The Ireland-based business, founded in 1976 as a manufacturer of exterior PVC and canvas coverings for machinery, vehicles and boats, has replaced old HP technology with the new 5m LED printer.

The dedicated roll-to-roll Vutek Q5r platform includes Y slitters – single or double-bladed – for separating multiple jobs on a single, full-width roll and minimise media waste. An automated ‘roll and tape’ function takes printed cut sheets directly from the printer, rolls them into scrolls and tapes their edges with labels containing printed job information. Automatic Backlit supports multi-roll cutting and slitting, enabling independent printing on each side of the material using a different print mode.

With nine colours and a print resolution of 1200dpi, the Vutek Q5r is suitable for high-definition image quality. Utilising cool cure LED, it extends the range of supported substrates including lower cost and added-value materials. Glossy and matt coating modes in either selective or full flood provide print enhancement and a protective coating for up to three years.

CoverUp’s operations director Anthony Byrne said, ‘The Q5r has instantly had an impact on production. It is really going to help us do what we do now but even better. PVC, canvas, Artex, vinyl and backlit – anything that’s possible to print – that’s what we’ll be doing.’

The company has since been experimenting printing UV images for lightboxes and blackout for display in addition to its traditional digital dye sublimation output. The UV printer also has a wide range of application capabilities including double-sided printing, textiles and more. CMYUK and Cover Up were the first in the world to purchase the Vutek FabriVU 340i back in 2018 when the company was looking to replace its M-Tex printers.

Mr Byrne added, ‘The FabriVU 340i was the best we could find on the market at the time for direct printing and inline direct fixation.

‘We didn’t want to go down the paper transfer route because that’s not the market we’re in. We get called up and asked if we can print a banner for next day delivery. Printing the roll and then putting it through a heat press wasn’t the way for us.’

CoverU offers a wide variety of applications including dye-sublimated textiles for soft signage through to rigid signage, flags, banners, and building wraps. It operates from two sites in the Dublin region – Sandyford and Clondalkin – and employs 16 staff.