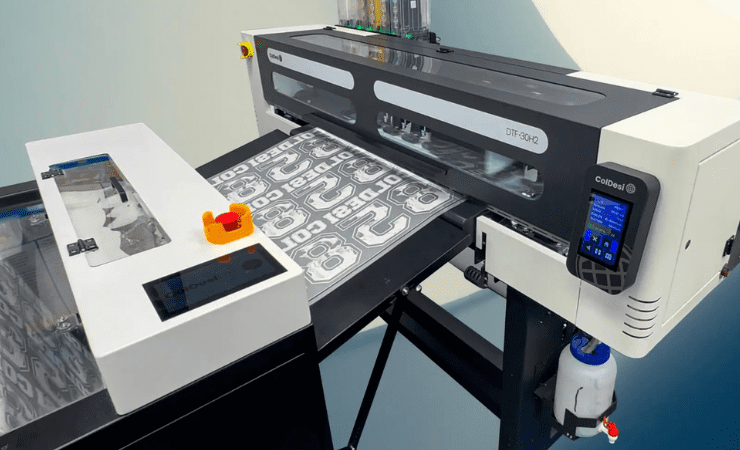

ColDesi Global has introduced the 30H2 Direct-to-Film (DTF) printer, designed for large-scale custom apparel production. The launch marks the company’s expansion into the European market, where demand for high-volume and precise garment printing continues to grow.

The 30H2 is intended for industrial environments, capable of producing hundreds of designs or thousands of transfers per day. It supports printing on cotton, polyester, and blended fabrics, delivering full-colour transfers with durability suited for commercial use.

The printer is supplied with the POW Series Shaker/Dryer systems, which include integrated fume extraction to filter oil vapours during the curing process. This setup is designed to improve air quality and reduce the need for additional ventilation equipment.

Equipped with dual printheads, the 30H2 is designed to balance production speed and print quality. Operators can use ColDesi’s Print Optimizer Software to manage ink levels, colour accuracy, and job configurations.

The inks used in the system are OEKO-TEX Eco Passport certified, meeting environmental and textile safety standards. ColDesi Global said this reflects its ongoing efforts to support sustainable apparel decoration practices.