Italian printing company Elle-Erre has expanded its production capabilities with new investments in digital textile printing technology from long-term partner Mimaki, as it adapts to growing demand for sustainable, high-quality print solutions in the events and sportswear industries.

Founded in 1992 and headquartered in Alzano Lombardo, near Bergamo in northern Italy, Elle-Erre has built its business producing printed materials such as advertising banners, large-format graphics, and custom displays. The company has steadily evolved from its event-focused origins into a diversified print service provider, with a particular emphasis on personalised, quick-turnaround work across various sectors.

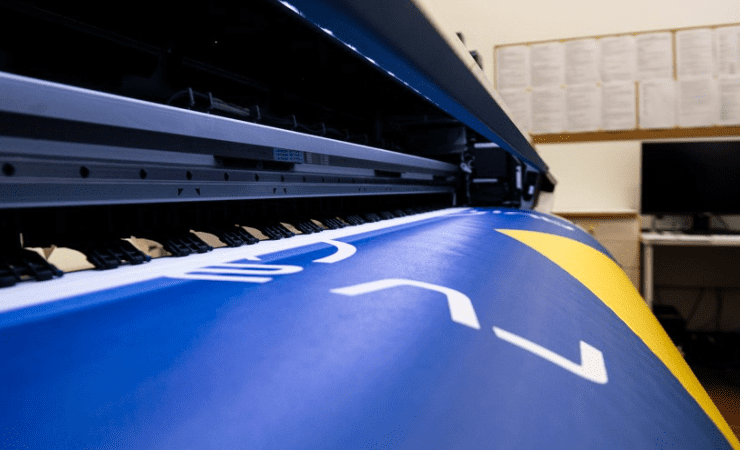

Responding to increased market demand for environmentally conscious and efficient production methods, Elle-Erre recently upgraded its operations with the addition of four Mimaki TS330-1600 dye-sublimation printers. These additions are part of a broader strategy to improve speed, consistency, and sustainability in textile production, particularly in fast-paced markets like sportswear and live events.

Elle-Erre began its digital transformation in 2010, gradually integrating Mimaki’s technologies into its workflows. The latest installations were chosen for their suitability in handling both short-run and high-volume orders, with software integration via Mimaki’s TxLink4 RIP allowing for greater automation and colour consistency. According to the company, the new equipment has enabled 24/7 production, reduced manual setup times, and improved output quality.

Owner of Elle-Erre, Gianluca Rota, stated that the technology upgrades have had a direct impact on operational efficiency. Since implementation, Elle-Erre reports a 30% increase in production speed and a 20% reduction in material costs, largely due to lower ink waste and streamlined processes. Mr Rota also noted that customer satisfaction has improved, with an increase in repeat business following the upgrades.

In addition to production gains, the company highlights environmental benefits as a core reason for its continued investment in digital technologies. Mimaki’s systems, which include features like MAPS4 and the Nozzle Recovery System, have helped reduce waste and ensure consistent print quality, aligning with Elle-Erre’s broader sustainability goals.

Elle-Erre plans to continue developing its digital capabilities as it responds to shifting industry demands. With Mimaki’s technology integrated into its operations, the company aims to maintain its competitive position in the Italian market while expanding its reach across Europe.