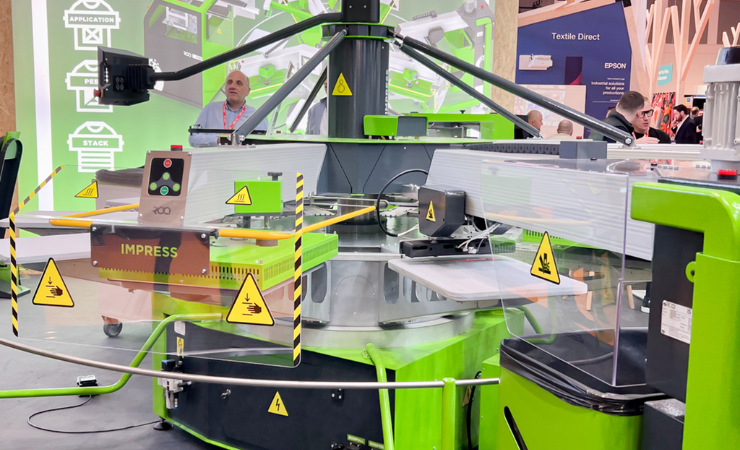

Manufacturer of machines for the textile industry, ROQ, has unveiled the latest evolution of its platform for transfer and DTF applications, the ROQ Impress P10C05 M.

Featuring 10 pallets and five heat-pressing stations, it has been designed to meet growing market demands by combining versatility, performance, and intelligent automation. The machine can reach speeds of up to 600 pieces per hour when equipped with combined pressing stations and complementary robotic attachments.

Key highlights of the ROQ Impress P10C05 M, according to the company, include the ability to have hot peel and cold peel on the same platform; a dual-function pressing station; hot peel with four combined heat presses for faster production speed and better finish; two pressing stations with Ø63 mm cylinders for +25% pressing power; and a built-in chiller for temperature control and operational stability.

The line is completed with the new ROQ Pull+, an automatic unloader with a redesigned stacking system. Using a pivoting arm, the system guides each batch into a gripping mechanism to ensure a precise transfer to the conveyor belt.

Focused on productivity and operational flexibility, the new Impress P10C05 M is a major step forward for companies looking to automate processes, increase output, and ensure consistent results in transfer applications, explained ROQ.