Epson is set to begin full-scale global commercialisation of Direct to Shape Printing System, an inkjet printing solution for printing directly on 3D objects. The company will showcase this solution at Automatica, in Messe München, Germany which runs from the 24-27 June, 2025. This will mark the first overseas exhibition of the solution.

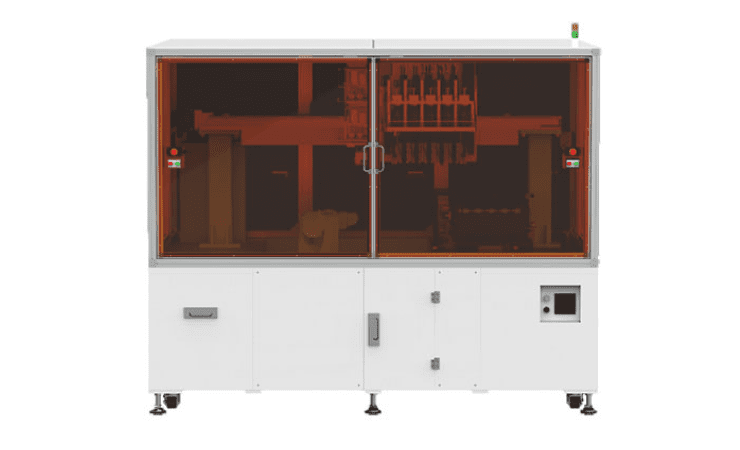

Direct to Shape Printing System combines the company’s S800 PrecisionCore printheads with an Epson industrial robot. The S800 printhead is the smallest in Epson’s PrecisionCore series and prints at a resolution 600 x 600dpi. This suits the application of printing on complex shapes, allowing the ink to reach in between grooves and curves. A six-axis robot and lifting mechanisms that independently raise and lower the printheads are used in combination to allow Direct to Shape Printing System to accommodate printing on objects from different angles with quality and accuracy.

Epson said its system digitalises analogue printing, streamlining manufacturing processes by automating manual tasks and using space efficiently. The company added that a benefit of the machine is that it only deposits ink where and, in the volume needed, which reduces the amount of material used and wasted.

The company expects that the system will be used where there is demand for printing on 3D shapes, such as helmets for athletics and industrial use, automotive parts (interior and exterior), home appliances, sporting equipment, apparel and accessories. In addition to graphics applications, Epson envisions Direct to Shape Printing System being used in functional printing, such as the printing of sensors with conductive ink and the coating of 3D objects.