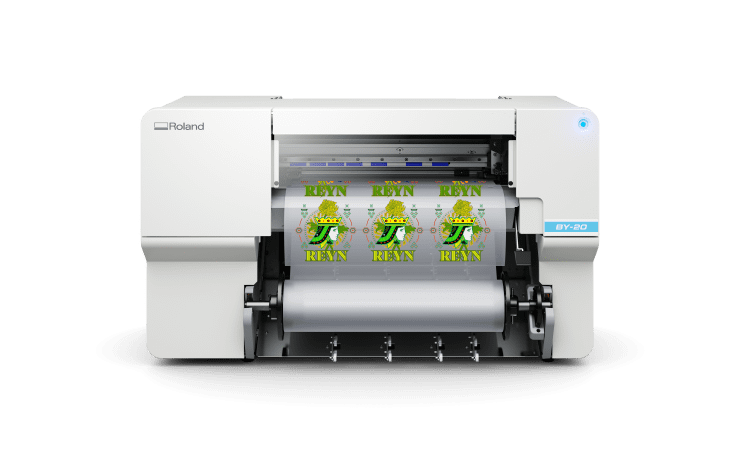

Manufacturer of wide-format inkjet printers and printer/cutters, Roland DG, has enhanced the ink and functionality for its VersaStudio BY-20 desktop DTF (direct-to-film) printer, creating additional capabilities and potential for users.

The BY-20 has been described by the company as a compact, easy-to-use, and affordable desktop printer using the DTF transfer method for professional apparel production. After printing on a special film, hot-melt powder is applied and thermally melted, and then the film is layered on fabric and heat-pressed to create original graphics for an array of garments such as T-shirts, sportswear and tote bags.

Roland’s S-PG2 ink

Amongst the improvements, the new S-PG2 Ink, which was created for Roland’s high-end DTF printers, is now compatible with the BY-20. Roland said this enables more stable and higher quality printing than before.

Maintenance functions on the BY-20 have also been improved. A new cleaning liquid allows users to clean the printheads more efficiently, and a new head nozzle refresher which makes the manual cleaning of the printheads’ surface easier. Manual maintenance prevents printhead nozzles from misfiring and enables more reliable operation.

Exclusive VersaWorks 7 (VW7) RIP software, included with the BY-20, now provides auto colour generation for the white ink layer, which is used in DTF printing as a base coat, and is now compatible with the PNG format (available September 2025). VW7 saves time for creating white ink layers which previously required using separate design software.

Ryugo Nimura, president of global sales and marketing division, said: “DTF printers are prone to harden the inks compared with traditional inkjet printers. With these new enhanced functions, we can provide a more stable working environment by enabling optimum printhead maintenance.”