Avery Dennison has unveiled advancements to its Optica solutions portfolio, aiming to meet growing demands for greater transparency, efficiency, and sustainability, addressing the key pain points for the apparel industry. Through partnerships with TrusTrace and GPRO, the company is addressing stages of the supply chain, from raw material sourcing to production line operations.

The first development is a partnership with TrusTrace, a traceability and compliance platform, to bolster materials traceability within Optica. This collaboration allows brands and retailers to gain verifiable insights into the origins and movement of raw materials. With capabilities to map upstream supply chains and establish chain of custody, brands can support sustainability claims, improve regulatory compliance, and meet consumer demands for ethical sourcing.

“Materials Traceability focuses on mapping the upstream supply chain and ensuring transparency of raw materials,” said Delia Glover, vice president of product, innovation, and solutions development at Avery Dennison. “It enables responsible sourcing and helps brands build trustworthy sustainability narratives.”

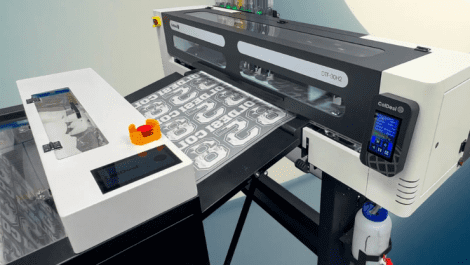

Complementing this, Avery Dennison has introduced a new Work-in-Progress (WIP) Tracking solution in collaboration with GPRO, a provider of RFID and Industry 4.0 technologies. This tool gives manufacturers real-time visibility into work order progress on the production floor, helping to identify bottlenecks, balance production lines, and reduce lead times.

The WIP Tracking solution, built on RFID technology, integrates with existing client systems and supports data-driven decisions by digitising factory operations. Early pilots in key manufacturing markets have shaped the solution, which is now a central feature of Optica’s production visibility offerings, explained Avery Dennison.

Ms Glover added: “By combining these solutions, brands gain a seamless, end-to-end view of their supply chain. This enhances compliance, improves decision-making, and reduces both sourcing and production risks.”