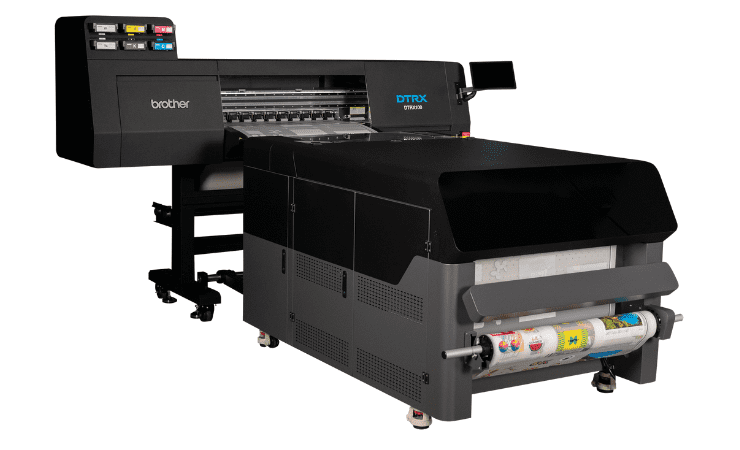

Brother has announced the launch of the DTRX, a new industrial-grade direct-to-film (DTF) printing system aimed at professional, high-volume garment and textile production environments. The system was officially introduced in January and will be available for purchase from February through Brother’s certified dealer network.

Positioned as an all-in-one DTF solution, the DTRX has been developed to meet Brother’s internal industrial standards, with an emphasis on reliability, repeatable output, and continuous operation. The company says the platform draws on its long-standing experience in industrial and garment printing technologies, and is designed for businesses looking to scale DTF production without compromising stability or workflow efficiency.

In production mode, the Brother DTRX delivers print speeds of up to 15 m² per hour. It features a 78 cm print width and supports roll widths of up to 80 cm, targeting large-format graphics and consistent, high-volume output. Brother states that the system is intended for demanding production schedules, where predictable throughput and uptime are critical.

The printer incorporates Brother’s industrial printhead technology, which is designed to deliver sharp detail and consistent colour reproduction across runs. The DTRX also uses newly developed Brother inks, described as sustainable and engineered specifically for this platform, with a focus on durability, colour vibrancy, and reduced environmental impact.

To reduce downtime and operator intervention, the DTRX includes an industrial maintenance station with automatic ink circulation and a wet wiper cleaning system. These features are intended to minimise manual maintenance and support stable operation in continuous-use environments. According to Brother, the system has also been designed for seamless integration into existing production workflows, allowing print businesses to increase capacity without major changes to their current setup.

“The Brother DTRX is built for real-world production,” said the company. “It is designed to perform reliably day after day on the production floor. With the DTRX, customers benefit from Brother’s proven engineering, global support network, and production-ready technology they can rely on.”

Key features of the Brother DTRX include production speeds of up to 15 sqm/hr, a 78 cm print width with 80 cm roll support, industrial Brother printheads, sustainable inks developed for the system, and automated maintenance functions designed to support high uptime.